In this article, you'll discover the pivotal role order picking plays in your warehouse profitability, and how it influences customer satisfaction. Additionally, you'll understand the common goals of order picking, explore various order picking methods, and learn how different equipment and technologies can improve efficiency in your warehouse operations.

Key Takeaways:

- Efficient order picking can significantly enhance warehouse operations and customer satisfaction, thereby impacting profitability.

- There are different methods of order picking, each with its pros and cons, which can be chosen according to the warehouse size and business volume.

- Effective warehouse management can minimize pick errors, travel distance, and injury risk, maximizing space utilization.

- Selection of order picking equipment heavily depends on the warehouse layout, and proper use can avoid accidents and enhance efficiency.

- Advanced technologies like voice-assisted picking and mobile order picking are improving the efficiency and accuracy of order picking processes.

Studies show warehouse order picking accounts for around 50% of a warehouse’s labor costs. Georgia Tech reports that the number can be as high as 63%. With the rise of ecommerce, selecting the best warehouse order picking method has become more important. Why? Because while other operations in your warehouse can be automated, order picking largely remains manual. Technology can be brought in to help your pickers, but that technology can’t replace them. So how do you help your employees perform their best, reduce costs, and increase order picking productivity?

Our Order Picking Methods guide will go over the following:

1) How Does Order Picking Impact Your Warehouse Profitability?

Order picking directly impacts your warehouse operations, and indirectly impacts other areas of your business. Your order pickers’ speed can keep your warehouse on track for order fulfillment, or it can put kinks into your schedule.

The results of your order pickers’ work affect your customer satisfaction levels as well. No one likes to receive the wrong products or too few of what they ordered. According to a small study of 500 customers, 54% said they returned a product because the seller sent the wrong item.

Your reverse logistics process is already getting a workout. The return rate for online purchases is about 20%. In order to keep your business margins healthy, you have to do what you can to lower costs.

BONUS: Before you go any further, download our Order Picking Strategies guide where we compare order-based, cluster, and batch-picking methods to see which method leads to the highest productivity.

2) Most Common Order Picking Goals

Yes, the goal of order picking process is order fulfillment. However, there are a few common internal order picking goals most warehouse managers strive for. These goals keep your employees productive, effective, and healthy. They also optimize your picking process. All of these goals work towards the bigger goal of a more efficient (and profitable) warehouse.

Minimize Travel Distance

An order picker spends half of their time traveling from one item to the next. So many managers seek to improve this time with good reason. Much of the warehouse technology related to picking helps the picker move from place to place. Advanced warehouse management systems provide picking path optimization algorithms to improve pickers' walking paths. The equipment you use often depends on your warehouse layout.

Maximize Use of Space

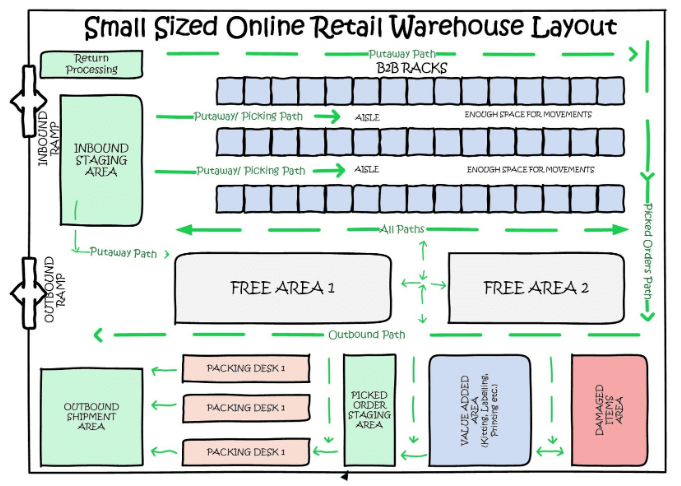

An optimized warehouse layout design goes far in improving picking efficiency. Your warehouse’s flow should be specific throughout the entire warehouse. You should be able to map it out, like the image below.

Minimize Pick Errors

Minimizing picking errors on the front end means you won’t have to put that item back on the shelf when your customer returns it. Returns in the U.S. are expected to reach $550 million by 2020. The order return process (taking a product from the customer and putting it back in your warehouse) can be very costly.

Minimize Injuries

Picking duties put pickers at greater risk for musculoskeletal disorders (MSD’s). In 2013, MSD’s accounted for 33% on work-related injuries. Warehouse workers came in second for the highest number of MSD’s that year.

Injuries increase factors like workforce churn. You also end up with a lot more uncertainty in your daily operations. With workers absent, there are fewer people available to perform the same amount of work.

3) Warehouse Order Picking Methods

When business is booming, adding more labor is a short-term fix. As customer demand increases, maintaining efficient operations is critical to a well-functioning warehouse. Avoiding bottlenecks, ensuring accurate orders, and keeping up with customer expectations regarding shipping times is easier if you’re using the right tactics.

An important tactic to consider is your order picking methods. Simplified methods work well for small businesses, but, as your company grows, you’ll need to consider more efficient ways of storing, sorting, picking, and packing your warehouse goods.

Simply choosing the most advanced order picking method isn’t always a good idea. If your business’ volume doesn’t justify an expensive, automated solution, the initial investment may not be worth it.

Additionally, clunky technology that requires high-volume inventory management won’t earn a return during low periods.

Pick to Order (Discrete Order Picking)

Overview

Pick to order is the simplest order picking system and goes by many names, including “discrete picking” and “picking by SKU.” Essentially, an employee receives a list of orders and walks the warehouse to pick the products before packing and shipping them.

If you run a small business or a relatively small warehouse, this method makes a lot of sense. It’s a relatively accurate, low-cost approach that requires no technology or order fulfillment system.

Advantages

The main advantage of the pick-to-order methodology is the low startup costs. As long as you have goods to pick and staff to pick them, you don’t need to implement any technology or spend time organizing pick zones or schedules. Workers simply receive a list of orders and get to work.

Of course, you’ll need a very organized warehouse to keep a pick to order operation efficient. If your warehouse shelves aren’t properly organized, workers will spend a lot of time looking for products, increasing the amount of time it takes to ship products to customers.

Disadvantages

A pick-to-order operation is manual. While this makes sense for a small business or small warehouse operation, it isn’t scalable.

One major mistake warehouse operators often make is adding more workers when business picks up. If there’s a one-off increase in demand, like a huge order or a seasonal cause, simply adding more bodies makes sense.

On the other hand, if your business is growing overall, you’ll need more efficient order picking processes so your workers don’t spend more time going back and forth than they do fulfilling orders.

Batch Picking

Overview

The batch picking methodology combines products for multiple orders into one pick instruction.

What do we mean by that?

Let’s say three different customers order a combination of products, such as:

| Customer A | 3 toothbrushes, 2 tubes of toothpaste, 1 bar of soap |

| Customer B | 2 toothbrushes and 1 bottle of mouthwash |

| Customer C | 1 toothbrush |

Rather than handling each order individually (e.g., a worker walks the warehouse for Customer A’s products and ships them before making another trip for Customer B), a worker will pick all of the toothbrushes required for Customers A, B, and C and bring them to a dedicated sorting area.

They will then make another trip for the toothpaste, and so on and so forth. Once all the “batches” have been picked and brought to a dedicated sorting area, workers sort them by order and then pack and ship them.

Advantages

Batch picking makes sense for warehouses with lots of SKUs and multi-product orders. Workers make fewer trips and maximize their pick volumes, thereby saving time and increasing warehouse efficiency. Plus, with fewer sporadic picks, there are fewer people moving through the aisles at once, drastically reducing the number of bottlenecks and allowing workers to get where they need to be sooner.

This method supports your warehouse layout optimization efforts as well. If employees pick based on locations, rather than orders, you can spread your most popular SKUs out evenly in one section of your warehouse. This enables more workers to pick those SKUs at the same time.

Disadvantages

The batch picking model isn’t a good fit for every business. If you opt to use this approach, it has to make sense for your operations. If you run a small warehouse with narrow range of SKUs and few customers or destinations, a standard order picking method may be more appropriate.

Another disadvantage: orders must be sorted and consolidated after picking, adding time to the overall process. This may not be a disadvantage for you if you use a warehouse inventory management system that supports advanced picking methods.

Wave Picking

Overview

Wave picking is much like batch picking, except orders to be picked are assigned in waves throughout the day. When orders are picked depends on specific criteria such as the carrier transporting them or the kind of packaging an order needs. Wave picking relies on an automated picking system(such as a WMS) to keep the process organized.

Advantages

Wave picking allows warehouses to organize their operations in a way that takes factors like labor and transport schedules into consideration. Workers pick goods at the most optimal times, resulting in highly efficient operations.

Disadvantages

Like batch picking, it requires additional time for sorting, packing, and eventual shipping. In order to work properly, wave picking requires the implementation of a supply chain software.

Zone Picking

Overview

Zone picking, otherwise known as pick and pass, is an enhanced version of batch picking. Workers are assigned to specific locations or zones, and order cartons move through those zones.

Each carton is associated with a specific order. To retrieve a SKU, the carton goes to that SKU’s area, where the assigned worker picks the required items and throws them in the carton. The carton then travels to the next location.

If an order doesn’t need SKUs from a particular zone, the carton skips that zone. In addition to implementing a system, warehouse managers who want to implement a zone picking strategy must invest in a warehouse control system for moving cartons.

Advantages

Zone picking reduces warehouse motion waste by keeping workers in one section. Moreover, large orders can be fulfilled more quickly, which can build customer satisfaction and lead to repeat business.

Another advantage of zone picking is reduced training costs. For instance, some zones may require forklift operations while others only require manual picking. So, only workers in specific zones will need specialized forklift training.

This also means you can recruit faster and easily keep tabs on who can and can’t use specific equipment.

Disadvantages

With zone picking, it can be hard to assign responsibility for inaccurately picked orders since there’s no single owner of the order. In addition, without a conveyor system, a separate area of the warehouse must be dedicated to order sorting.

Finally, if demand fluctuates, some zones will have more work than others, potentially leading to an uneven division of labor on the floor. In scenarios like this, it may make sense to rotate the schedule.

Cluster Picking

Overview

Using multi-tote or multi-bin contraptions, workers will pick items for multiple orders at the same time. Imagine walking through a supermarket with three different shopping carts: one for yourself, one for your neighbor, and one for your friend. In a nutshell, that describes a cluster picking operation. You make fewer trips while filling a greater number of orders.

Advantages

Cluster picking allows workers to fulfill multiple orders without walking the floor numerous times. A consolidated order list helps them stay on top of orders and pick them accurately. Each picking shift can consist of anywhere from 4 to 12 orders, increasing the amount of goods shipped to customers on a given day.

Disadvantages

A cluster picking operation requires a sophisticated software system to ensure clusters are scheduled and assigned properly. At the end of the day, cluster picking is only as efficient as the system masterminding it.

While this isn’t a disadvantage in and of itself, it should be a significant consideration for companies who don’t have the startup capital or the willingness to commit to implementation.

Order picking accounts for 50% of your warehouse operational costs. Make sure you’re using the most cost-effective order picking strategy by reading our detailed guide where we compare the 3 most common order picking methods.

4) Order Picking Equipment

The sort of equipment you have in your warehouse is largely dictated by your warehouse layout. Certain types of equipment will only fit in aisles of a certain width for example. When selecting equipment for your warehouse, you must also consider the resources required to get your employees trained to use it.

Of course, proper use is critical to a smooth-running warehouse, but also to keep your employees safe. Let’s take the forklift for example. This extremely common piece of warehouse equipment causes 95,000 injuries every year.

Picker to Goods

Much like the name describes these types of equipment focus on getting the picker to the goods as quickly as possible. Cutting down on your picker’s transportation time makes for faster picking times.

- Trolley and Roll-Cage Pallets: Your picker pushes a trolley or roll cage pallet around, putting the required goods inside. Some trolleys have shelves or are structured to accommodate plastic bins or totes.

- Order Picker Forklift: Not to be confused with a traditional forklift, an order picker forklift lifts the operator so they can manually move goods on and off the order picker.

- Semi-Automated Trucks: This type of truck is guided automatically to picking locations, often by laser. The picker picks until the truck is full, and then the truck returns to the dispatch area.

Goods to Picker

This category of equipment leans more heavily on more modern warehouse technology or warehouse robotics. You can see more potential for warehouse automation in these equipment types.

- Warehouse Carousels: You can have either vertical or horizontal carousels, depending on your warehouse layout and design. Using computer control, goods are presented to the picker to place in customer order bins.

- Totes-to Picker Systems: Your employees will use a computer to direct the extraction and presentation of certain totes to pickers for order assembly. The totes usually travel a conveyor to the picker. Your pickers will consistently receive totes for the orders they’re putting together.

- Shelf Modules-to-Picker Systems: This system is very similar to the totes-to-picker system, except entire shelving units are presented to your picker. Robotic drive units, taking computer direction, will present shelving units to the appropriate picker station. Also called a robotic butler, the bot will return the shelf module to storage, or present it to another picking station.

Latest Order Picking Assistive Technology

We would be remiss if we didn’t include a section about some of the latest innovations that assist your order pickers in their work. Two of the biggest tech upgrades for order pickers are voice technology and mobile picking.

Voice Assisted Picking

The primary piece of equipment is a microphone headset worn by your pickers. They can receive audible instructions about where to travel and what to pick. This leaves them hands-free, with no paper slips to deal with.

Mobile Order Picking

If all of your inventory is fitted with a unique barcode, then a mobile scanning technology may be a great fit for your warehouse. A WMS can push picking information to your pickers’ mobile devices, along with the ideal picking route. You pickers can achieve almost perfect picking accuracy with this system, since their information is fed directly from the customer’s order to their mobile devices.

5) Your WMS and Your Order Picking Equipment

Some order picking equipment, like trolleys, have been around for quite some time. As technology continues to penetrate the supply chain industry, we're even seeing upgrades on that sort of equipment. Like automated trolleys that follow order pickers as they move about the warehouse.

Your software is the information highway that connects all of these different points in your warehouse and the rest of your supply chain. A fully integrated software will communicate with your warehouse stations and the equipment.

Increase Order Picking Productivity with an Integrated System

In order to use the advanced order fulfillment strategies we’ve described to their fullest potential, you need an order fulfillment system. By automating tasks like order picking lists and packing lists, you free up your warehouse staff to take care of the tasks that really require their attention. If picking takes up 50% of your warehouse budget, make sure those resources are used to maximum impact.

As the most integrated warehouse management system on the market, Logiwa is the solution you're looking for if you need a solution to help you pick, pack, and ship faster. Click here to get a WMS demo more about what Logiwa can do for your warehouse performance.

FAQs: Order Picking Method

Q: What is an order picking method in warehousing?

A: An order picking method in warehousing is the procedure or system used to select, or 'pick', items from storage locations to fulfill customer orders. There are different methods, each with its own benefits and limitations.

Q: What are the common types of order picking methods?

A: Common order picking methods include piece picking, batch picking, zone picking, and wave picking. Each of these methods is suitable for different types of warehouses and order complexities.

Q: How does the piece picking order picking method work?

A: Piece picking, also known as pick-to-order, is an order picking method where items are picked one at a time according to the specific customer order. It's suitable for low-volume orders or businesses with diverse product offerings.

Q: What is the batch picking order picking method?

A: Batch picking is an order picking method that involves grouping several orders together and picking all the items for these orders at the same time. This method is usually more efficient than piece picking because it reduces the travel time within the warehouse.

Q: Can you explain the zone picking order picking method?

A: Zone picking is an order picking method where the warehouse is divided into several zones and pickers are assigned to each zone. Each picker is responsible for picking all items in their zone for a specific order. This method increases efficiency by reducing picker travel.

Q: How is wave picking different from other order picking methods?

A: Wave picking is a combination of zone and batch picking methods. Orders are processed in waves throughout the day, with each wave designed to optimize the picking process. It allows for better management of pickers and equipment, and it can be particularly efficient when coordinated with shipping schedules.

Q: Which order picking method should I choose for my warehouse?

A: The selection of an order picking method depends on many factors such as the nature of your items, the size and layout of your warehouse, the volume and complexity of your orders, and your available resources. It's best to consult with a logistics or warehouse expert to determine the most efficient and cost-effective method for your specific needs.

Q: Can technology be integrated with order picking methods?

A: Absolutely. Many order picking methods can be enhanced by technology such as warehouse management systems (WMS), pick-to-light systems, barcode scanning, and even robotics. These technologies can significantly improve picking accuracy, efficiency, and productivity.

Q: What are the potential challenges of implementing an order picking method?

A: Implementing an order picking method can involve challenges such as initial investment costs, training requirements, system integration issues, and potential disruption to ongoing operations. However, these challenges can usually be managed with careful planning, employee training, and phased implementation strategies.

Q: How can I evaluate the effectiveness of my chosen order picking method?

A: The effectiveness of an order picking method can be evaluated by metrics such as picking accuracy, picking speed, order cycle time, and costs per order. Regular evaluation and adjustments can help ensure your order picking process remains optimal as your business and market conditions change.

Related Terms

FedEx Drop-Off

With FedEx Drop-off, you can easily pick up and drop off packages near you. But is it really as easy as it sounds?

UPS Next Day Air Saver

UPS Next Day Air Saver is an inexpensive, yet effective way to ship objects fast and ensure timely deliveries. Learn how to bypass costly delays in this latest article by Logiwa

Eco-Friendly Packaging

Eco-friendly packaging has become increasingly prevalent to the world, as well as consumers. Learn about sustainable methods and the benefits of green packaging in this article by Logiwa.

eBay Seller Hub

eBay’s Seller Hub remains a top ecommerce site by offering centralized seller tools, data to increase profits and ease of usability. Learn how to navigate eBay’s Seller Hub in this latest article from Logiwa!

Retail Arbitrage

Retail arbitrage entails a simple process of buying discounted items from a retailer and reselling them at a higher price point, but there’s plenty of pros and cons to consider. Learn about the risks and rewards in this latest article by Logiwa.

The Leading Supply Chain Management Software for “New Age” B2C/B2B Fulfillment Businesses

Warehouse Management

Modern digital WMS powers a modern fulfillment experience

Inventory Management

Improve your inventory across your supply chain.