Key Takeaways:

- A pick list guides warehouse employees on which inventory items are needed to complete customer orders, detailing shipment information, warehouse location, and item specifics.

- The design of a pick list is influenced by the picking method employed, such as pick-to-order, batch picking, or zone picking.

- Digital pick lists, accessible via mobile devices, are gaining popularity due to their ability to reduce human errors and integrate seamlessly with Warehouse Management Systems (WMS).

- Including essential details like SKU, product description, warehouse location, and pick quantity can significantly reduce picking errors.

- Accountability in pick lists, with fields like "Picked By" and "Checked By," ensures a two-step verification process, enhancing accuracy in order fulfillment.

Picking List Guide: What You Need to Know (Free Picking List Template)

As you expand your warehouses, your warehouse operations costs will rise. Among all your warehouse operations costs, labor accounts for 60-70%.

Order picking accounts for more than 50% of those labor costs. Almost 70-80% of a warehouse employee’s time is spent on picking, which accounts for 60% of total warehousing costs.

Designing an efficient order picking process around a clear and streamlined picking list is vital to making the most of your labor hours. You can also eliminate costly errors during fulfillment.

In this guide, we’ll cover all the details you need to include when designing a pick list:

What is a Picking List?

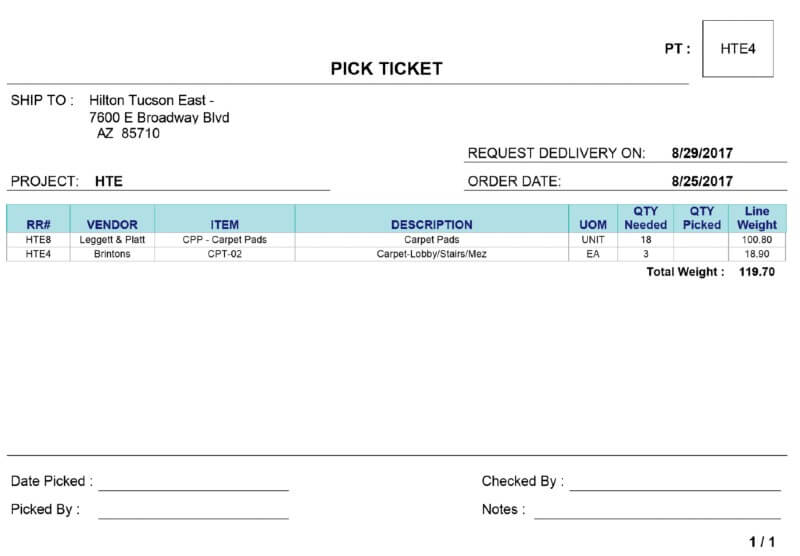

A pick list tells your employees which inventory is needed to fulfill customer orders. Generally, a pick list shows the shipment information, warehouse location, and item information. Once you’ve received customer orders, you can generate pick lists for your warehouse pickers.

If you have a warehouse management system (WMS) or an inventory management system (IMS), pick lists are generated automatically when your customers complete an order.

Picking lists are also known as pick tickets or pick lists.

Startups and smaller operations with low order volume may pick-to-order as those orders come in. As businesses scale, they often use a WMS which may include a custom designed picking list for batch picking or zone picking. We’ll get into picking methods in the next section.

With a pick ticket designed, warehouse staff will either use a digital system or printed copies to retrieve items for shipping.

Before the advent of mobile technology, printed picking lists were standard in warehouses. While less common now, it can still be an effective method. The biggest downside to printing a pick list is that your order picking productivity can be affected.

Digital pick lists can be pushed to mobile devices and are becoming more commonplace. A digital picking list helps reduce human error with product scanning, can track metrics on picker performance, and often integrates perfectly with a WMS to provide optimal routes through the warehouse.

Some people like to have an actual pick list in hand while fulfilling orders. Some warehouses won’t print the pick lists, and instead create jobs for their pickers. Whether your warehouse uses a digital picking list or a printed one is entirely your preference.

BONUS: Before you go any further, download our Pick List Excel Template to give you a head start in creating your own picking lists.

Pick List Design Depends on Your Picking Method

Your pick list design will vary depending on the picking method you use in your warehouse. That process depends largely on a few factors like:

- Total number of products sold

- Velocity and volume of orders

- Size of your business

It also may vary depending on whether you use manual picking vs picking automation.

Continue reading to learn about the most common order picking methods.

Pick-to-Order

This is the most basic method for picking product in the warehouse and is most commonly found in smaller warehouse operations with minimal products. This approach may or may not use a custom picking list. Some brands use the customer’s individual order receipt or packing slip to select the product to be shipped.

Using a picking list is still recommended in smaller operations as a pick ticket often limits the amount of non-essential information and data that pickers don’t need.

That’s ideal when a picker is pulling all the items per order one order at a time because any slowdown can cause significant shipping delays for that customer and others to follow.

Batch Picking

Batch picking is similar to single order picking, though there are some slight variations to the picking list. Rather than just the products for a single order, the picking list is designed to efficiently pick a number of orders in one trip.

Once all the products in the batch have been picked, the picker delivers the items to the packaging area. Then the products are sorted and packed in the appropriate orders for shipping.

Zone Picking

When you use this method, your picking lists will be product-based instead of order-based.

Each employee is assigned to a zone in the warehouse. As orders come in, the employee’s individual pick list populates with all the products that need to be picked within their zone. Once a list is complete, it’s delivered to the sorting and packaging crew to assemble the individual orders.

In this method, a single order could actually be split across multiple pick lists if the products on that customer’s order are spread out through multiple warehouse zones.

This approach is also known as wave picking.

In some cases, zone picking involves orders passing from one zone to another as products are picked for individual orders instead of batches. When all the products from an order are picked, the last zone/employee will hand off the order to be packaged and shipped.

Components of a Picking List

We’d like to emphasize that a picking list isn’t an order confirmation or customer receipt. Picking lists are internal documents that customers typically never see, especially if they’re digital.

For this reason, it’s ideal to only design a picking list with information that’s pertinent to the picker's job.

Including irrelevant information, especially number values, can distract a picker and result in errors.

While the data that’s in the picking list can vary depending on the picking method you use, there’s some standard information that’s likely to be included on the pick list.

Customer Information

Whether you work with multiple teams throughout the warehouse or your pickers are also the ones packing orders, it’s a good idea to include customer information on the picking list.

While not critical to picking, the customer's name and address allow cross-referencing when orders are packed to ensure the three R’s:

- Right products

- Right order

- Right customer

Picking List Number

The picking list number or pick ticket number should be unique and easy to find. This reference number makes it easy to review past pick tickets, find them in the system, and easily pull them for things like order audits and employee reviews.

Order Information

Because different teams may need to use and verify different types of order information, it’s a good idea to include the relevant order details in a few different forms. This includes clearly printing the:

- Date and time of the order

- Order number

When using warehouse management software or inventory management software that includes barcodes for orders, that barcode should also be printed on the picking list.

Your pickers may not scan the code, but when the picking list changes hands, the packing and shipping team may be able to use barcode placement to speed up the order processing and fulfillment processes.

Warehouse Location

Each product on the picking list needs to clearly state the exact location of the product within the warehouse. Depending on your warehouse’s size, this information could be complex, so clarity is critical.

This field will include the location of the pallet, aisle, shelf, bin, zone, etc. for each product.

SKU

The stock keeping unit (SKU) is incredibly important in the pick list, especially if you have multiple products with very similar SKUs. Pickers need to be able to easily identify a product SKU when comparing the items on the shelf or pallet to the picking list.

For example, if a picker is pulling a shirt with SKU 1876Tshirt-W (white) and it’s near other products with the SKU 1876Tshirt-B (black), and 1876Tshirt-R (red) a clearly marked SKU on the pick list can help avoid errors.

Product Detail/Description

You can avoid picking errors by adding the product name and description next to the SKU. A few descriptive words can make a difference when pickers are dealing with very similar SKUs or products carrying the same title/name.

Unit Size and Weight

This is more important in facilities that deal with a variety of products with significant variations in size and weight. An automated system can use this data during routing to ensure a picker has enough room in their vehicle or basket to pick all the required items.

It can also help the picker identify any items ahead of time that may require a two-person lift or specialized equipment.

Unit of Measure

This is only vital if products are sold in different units, such as by the case and individually. This way your picking list communicates whether or not the order calls for 1 or more individual pieces or an entire case.

Pick Quantity

There should be two fields in a picking list for the quantity of each product. One states how many should be picked, and another field where the employee indicates how many they actually picked.

Picking List Accountability

Even with a warehouse inventory software and a great picking list template, there’s always the potential for human error. For this reason, your pick lists should have fields for accountability.

When a pick list is completed there should be a “Picked By” field for the picker to sign indicating they verified that all the products pulled match products indicated on the pick list. In a case where a product couldn’t be picked for some reason, this signature also indicates an acknowledgment of any discrepancy.

If necessary, management can trace any issues with the products or customer order back to the picker.

The accountability segment should also include a “Checked By” field. This is for a second individual to verify that the products pulled match products indicated on the pick list.

The picker should never be the person who performs the final “Checked By” audit of the order before it’s packaged and sent to the customer. A two-employee check system greatly reduces any chance for errors.

Creating the Perfect Pick List

When brands design their own pick list, they typically include some or all of the information we’ve listed above. While any kind of pick list can be created using a spreadsheet and software like Excel or Google Sheets, it can be somewhat time-consuming.

Rather than design a custom picking list from scratch, save time by using a template to fit your needs. We offer a fully customizable Pick List Template to remove a lot of the headache from creating the perfect list.

FAQs: Pick List

Q: What is a picking list in warehouse operations?

A: A picking list is a document used in warehouses to guide employees on which inventory items are needed to fulfill customer orders. It typically shows shipment information, warehouse location, and specific item details.

Q: How does a picking list differ from an order confirmation or customer receipt?

A: While an order confirmation or customer receipt is meant for the customer and confirms their purchase, a picking list is an internal document. It's designed specifically for warehouse operations, focusing on details pertinent to the picker's job and is not typically seen by the customer.

Q: How does the design of a picking list vary with different picking methods?

A: The design of a picking list is influenced by the picking method used in the warehouse. For instance, pick-to-order lists might focus on individual orders, batch picking lists consolidate multiple orders for efficiency, and zone picking lists are product-based, focusing on items within specific warehouse zones.

Q: Are digital picking lists becoming more common?

A: Yes, digital picking lists are becoming more prevalent. They can be pushed to mobile devices, reducing human error through product scanning, tracking picker performance metrics, and often integrating seamlessly with a Warehouse Management System (WMS) to provide optimal routes through the warehouse.

Q: Why is accountability important in a picking list?

A: Accountability ensures that any discrepancies or errors can be traced back to the responsible individual. Fields like "Picked By" and "Checked By" on the picking list allow for a two-employee check system, significantly reducing the chances of errors during order fulfillment.