Agile real-time warehouse management software (WMS) for high-volume manufacturing

58%

improved task efficiency

38%

increase in productivity

Challenges

Legacy manufacturing warehouse management software (WMS) suffers from lack of visibility and limited scalability

Modern manufacturing warehouse software needs end-to-end visibility to automate tasks, reduce errors, and improve productivity. Logiwa IO manages inventory, streamlines packing, and optimizes warehouse space with real-time data.

Transform manufacturing fulfillment with AI-powered warehouse software from Logiwa

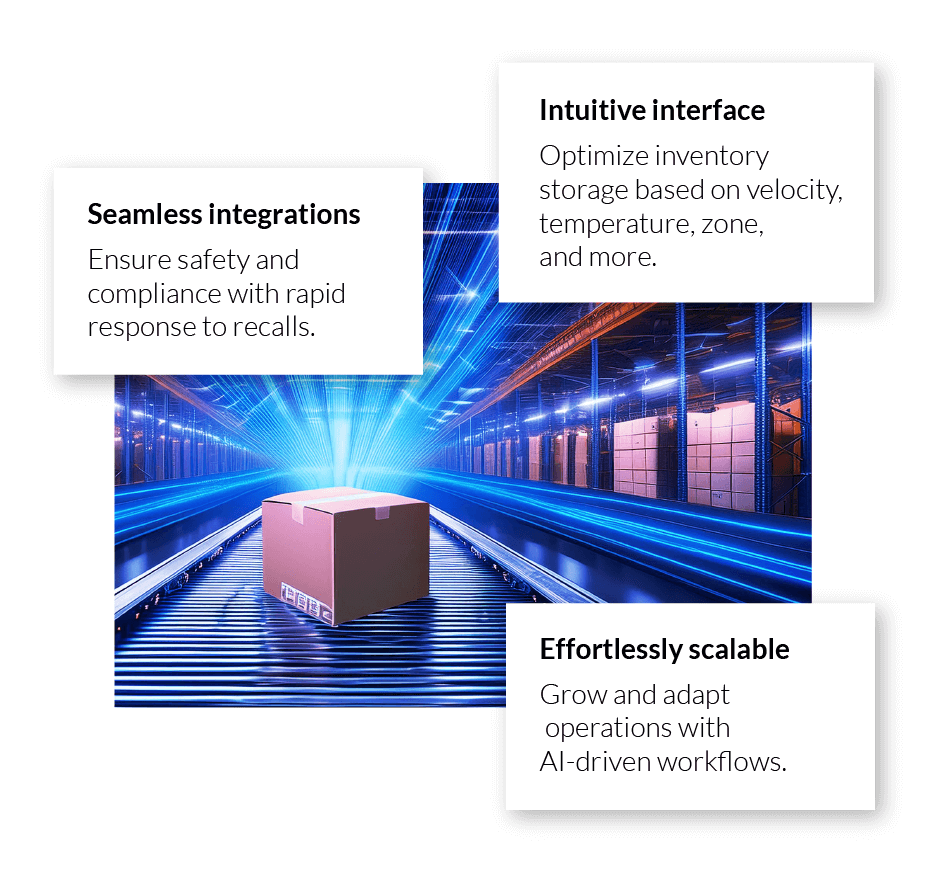

Logiwa IO’s seamless integrations connect suppliers, customers, and logistics providers to ensure visibility across the entire supply chain. By reducing manual work and improving efficiency, Logiwa manufacturing warehouse management software (WMS) allows teams to focus on quality and speed, making operations smoother and more precise.

Logiwa IO can help.

Schedule a call.

Solutions

Achieve peak productivity with smart warehouse management software for high-volume manufacturing operations

Logiwa IO is a modern fulfillment management system (FMS) with features that support both B2B and DTC functionalities—enabling manufacturers to thrive. Our comprehensive warehouse software addresses specific issues facing manufacturing today.

Activate your workforce faster

Logiwa IO’s modern user interface is unmatched in the industry. Easy to use, intuitive screens allow onboarding employees faster with minimal need for training. Ease of use leads to better efficiency and fewer errors.

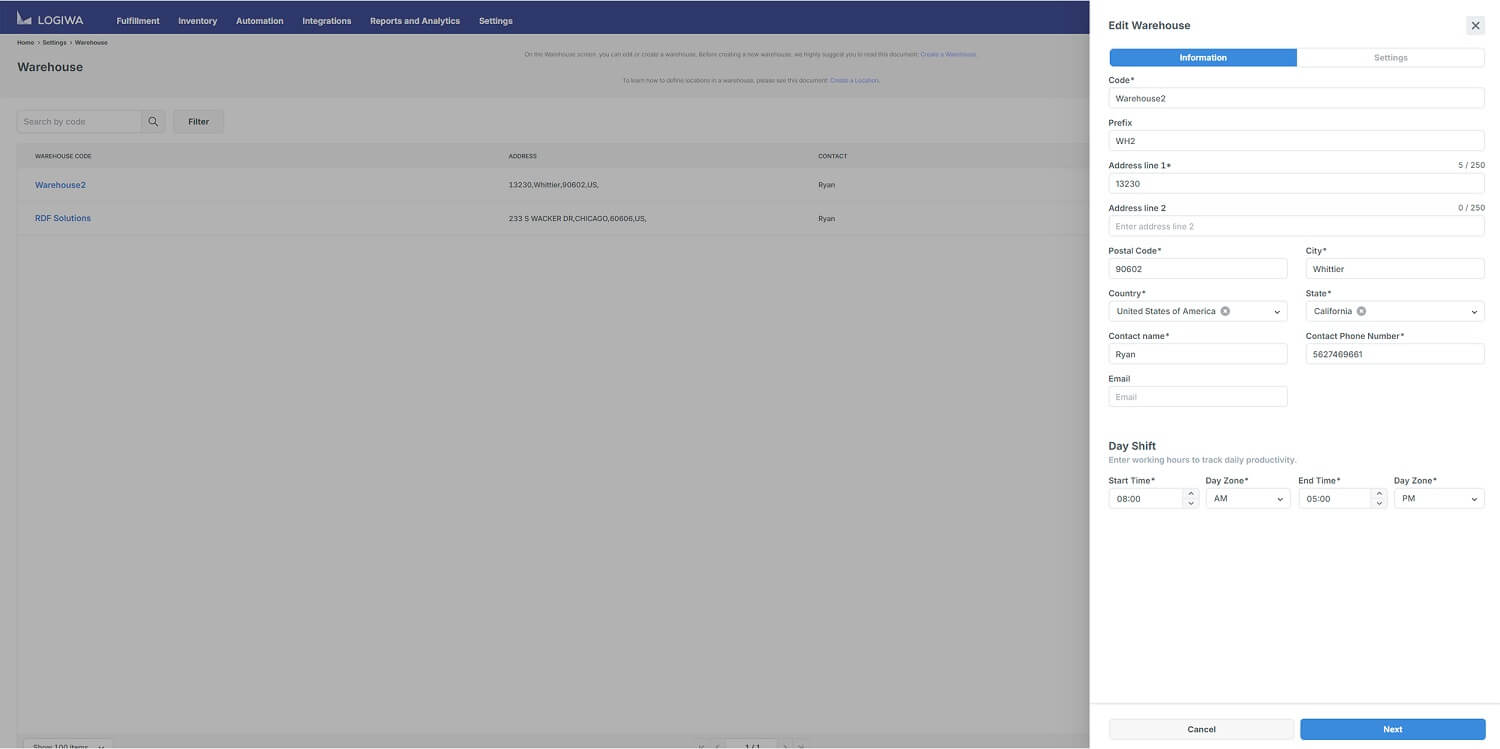

Flexible—scale and adapt with ease

Logiwa IO is built on a headless architecture. This means every action you take on our user interfaces has a matching endpoint (web service) that you can use to design and implement your own experiences beyond Logiwa IO.

Easily configured—no code required

Logiwa IO makes it easy to adapt to the needs of the market and new clients. Our no-code drag and drop workflow automation feature lets manufacturing warehouses deliver the best service to every client. Create workflows to address every need without the cost associated with custom development or professional services.

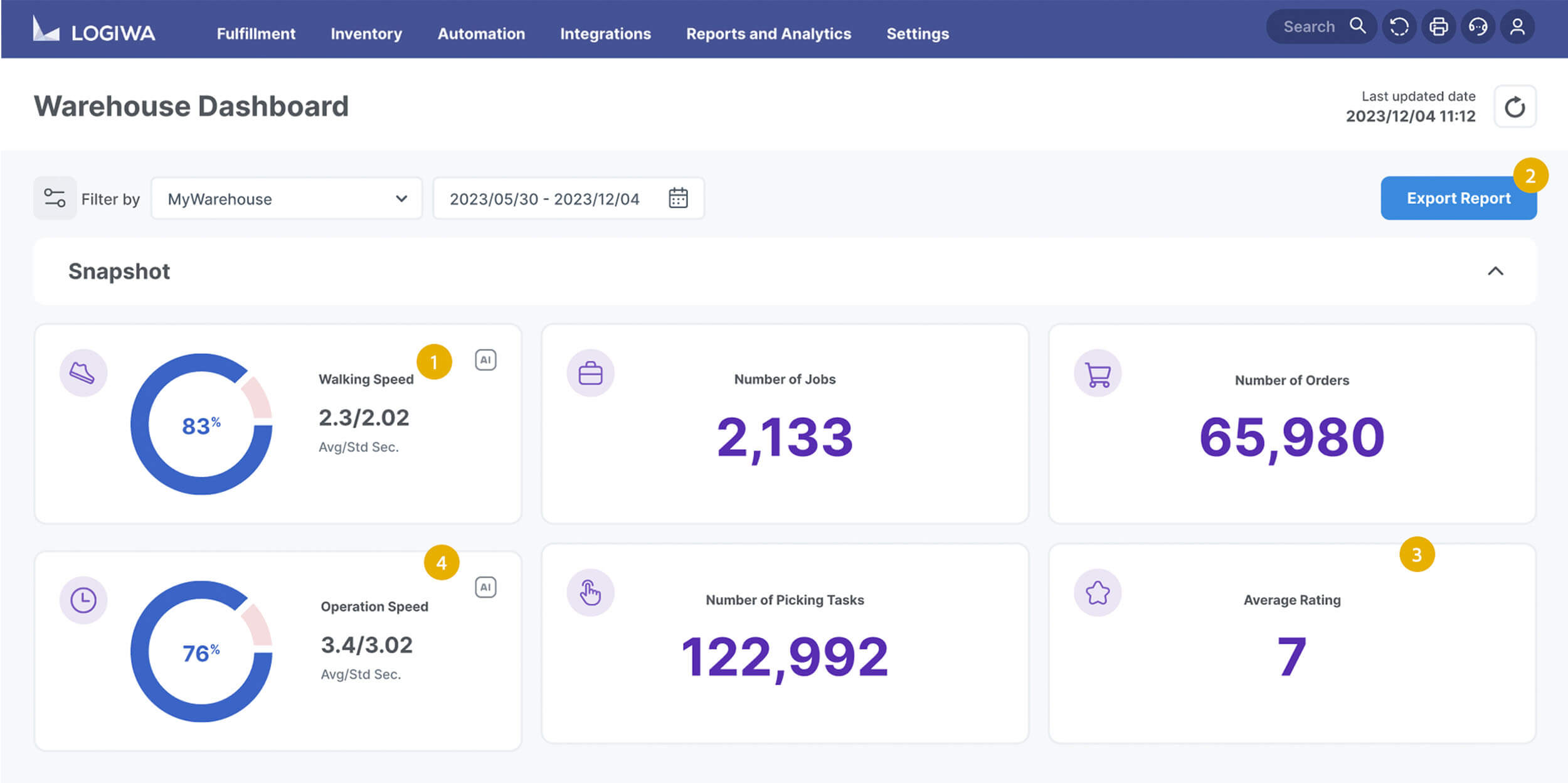

Your best warehouse manager

Logiwa IO’s AI-driven manufacturing warehouse management software continuously tracks order flow and available resources then automatically creates optimized jobs for your workforce. It’s like having 10 of your best warehouse managers working together 24/7.

Every step counts

Items picked per hour is only a small part of the story. Logiwa IO’s Labor Tracking and Reporting solutions continuously track all physical and digital activities completed via desktop and mobile applications. This unmatched visibility over your operations allows you to continuously identify opportunities for improvement.

Scalable volume-based pricing

Logiwa felt manufacturing WMS pricing models begged reassessment. How is it in your WMS provider’s interest to aim for efficiency when their revenue is dependent on the number of user licenses they sell you? That’s why Logiwa IO uses a volume-based pricing model. It aligns your goals with ours. It’s a win-win and another way we help 3PLs fulfill brilliantly.

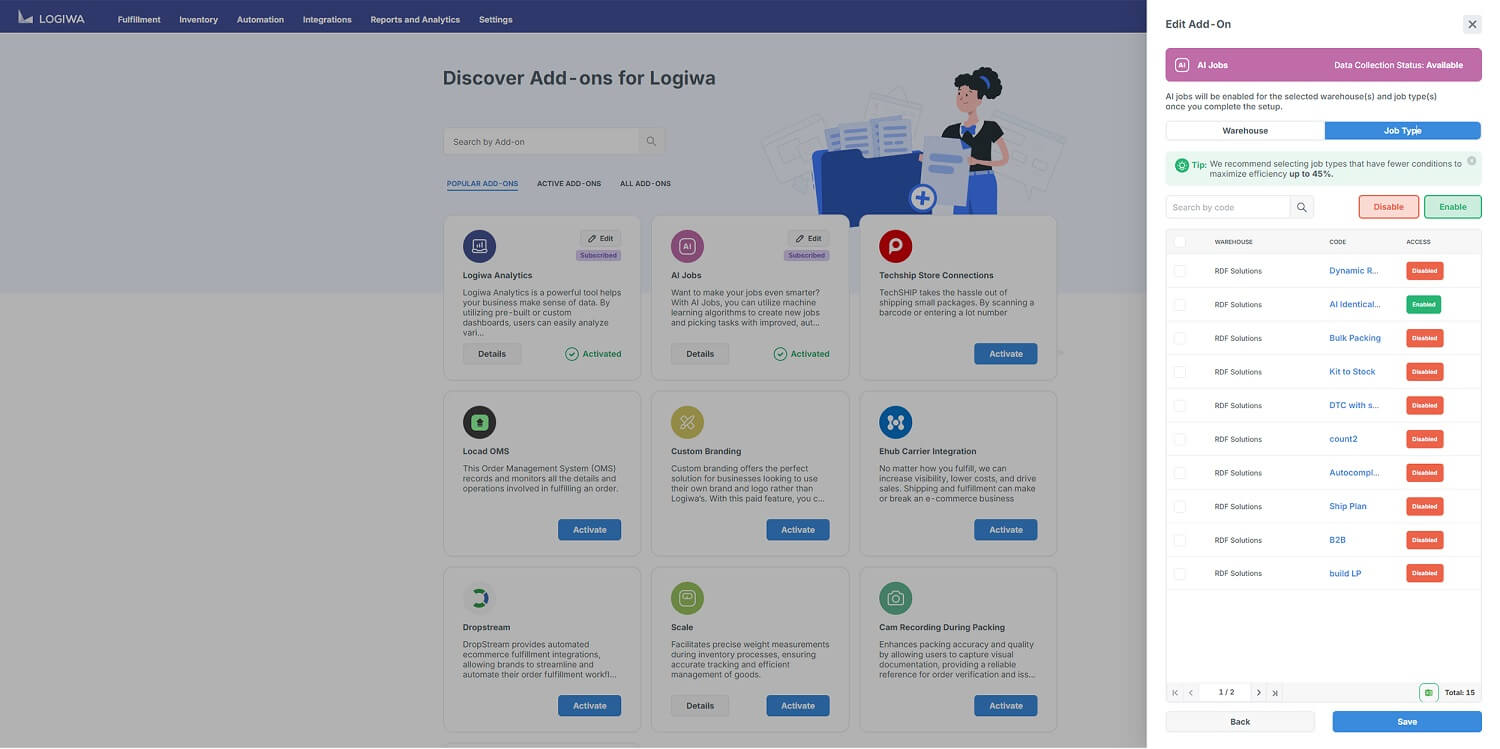

Choose any of the WMS functions to explore further

1. Product Management

2. Store Integrations

14. Inbound / Receiving

3. 3PL Billing

4. Client Management

5. Carrier Integrations

6. Rate shopping

7. Role Management

8. Users and Permissions Management

9. Multi pack type management

10. Location Management (Location Setup & Functions)

11. Kitting & Workorder

12. Lot, Expiry Date & Production Date Tracking

13. Barcoding (Print Item and Location Labels)

16. Inventory Adjustment

17. Mobile Scanning (Receiving, Transfers, Count, Picking)

18. Wave Manager

19. Packing Station

20. Exception Handling (Backorders, Missing Items, Reprint labels etc.)

21. Cycle Count

22. Returns Management

23. Replenishment

24. Client Portal

25. Workflow Designer (Order Automation Rules)

26. Job/Batch Type setup

1. Product Management

SKUs (stock keeping units)are internal codes used to track inventory and report sales. These unique identifiers streamline various business processes and enhance inventory management.

Features

SKU (Stock Keeping Unit) Management

Create unique SKUs for each product, which serve as the internal codes used to track inventory. SKUs can be identical to the product name and are essential for managing product identification, inventory tracking, and sales reporting.

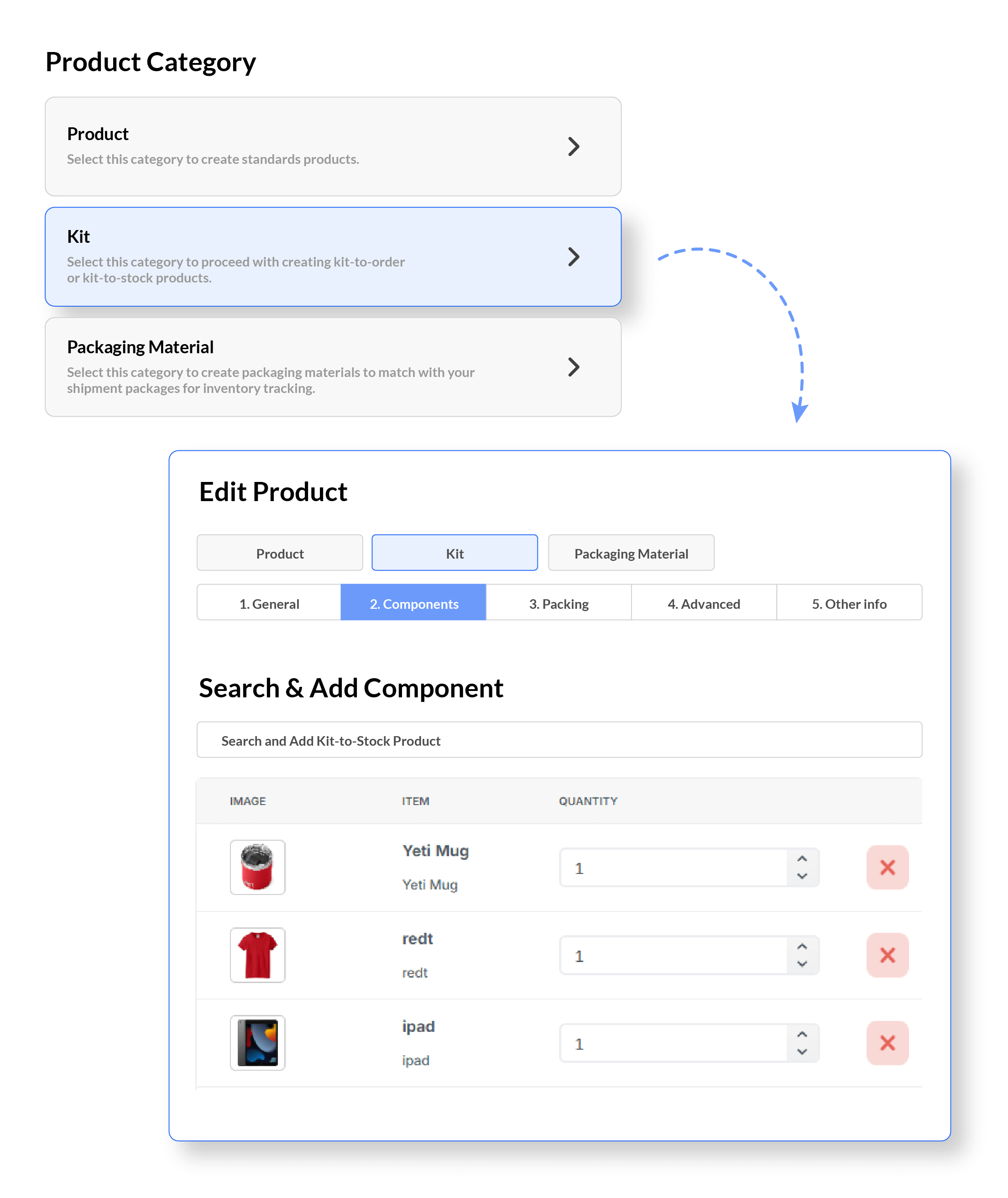

Kit Product Management

Create and manage kit products, which consist of multiple components. Logiwa IO supports both Kit-to-Order products, which are assembled at the time of order and do not require inventory storage, and Kit-to-Stock products, which are pre-assembled and stored in inventory. Kit products can be managed directly from the Products screen.

Packaging Materials Management

Manage packaging materials from the product screen, allowing for efficient handling of materials needed for packing and shipping operations.

Comprehensive Product Details

Enter detailed information for each product, including descriptions, images, product types, product groups, currency, and pricing (purchase and sales prices). This detailed data supports precise inventory management and reporting.

Packing and Handling Instructions

Add specific packing and return instructions, as well as selectable attributes (e.g., foldable, fragile, oversized), to improve packing efficiency and ensure proper handling of products during storage and shipment.

Pack Type Management

Define and manage different pack types for each product, including Primary (UOM), Irregular, and Hierarchical pack types. Assign barcodes and set dimensions, volume, and weight for each pack type to ensure accurate shipping and handling.

Advanced Tracking

Utilize advanced options such as lot/batch tracking, expiry tracking, serial number tracking, and production date tracking to maintain control over products requiring special handling or monitoring.

Custom Fields

Add up to 10 custom fields to further customize your product setup, including free text fields, toggles, and date pickers. These fields allow you to capture additional data specific to your operational needs.

1. Product Management

SKUs (stock keeping units)are internal codes used to track inventory and report sales. These unique identifiers streamline various business processes and enhance inventory management.

Features

SKU (Stock Keeping Unit) Management

Kit Product Management

Packaging Materials Management

Comprehensive Product Details

Packing and Handling Instructions

Pack Type Management

Advanced Tracking

Custom Fields

Customer Success

See what our customers say